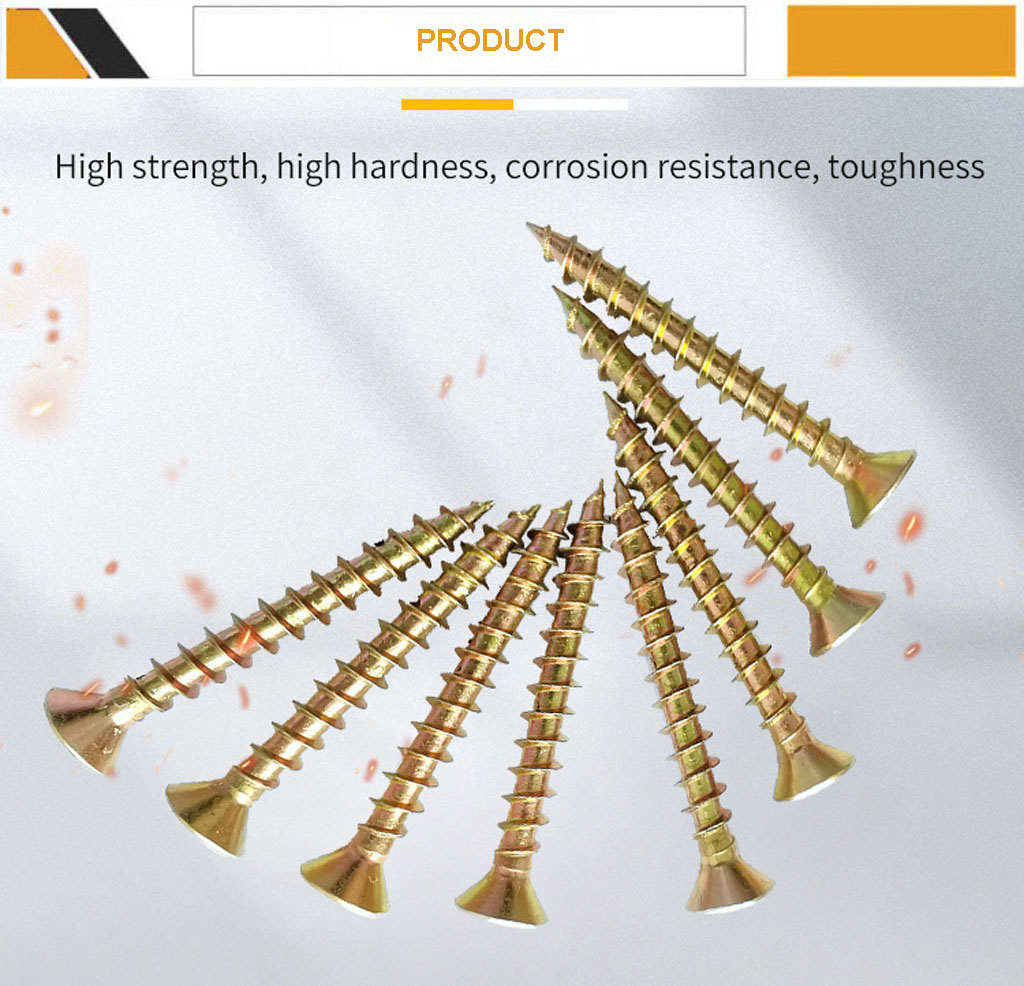

Yellow zinc torx drive double countersunk head wood chipboard screw

Chipboard screws, also named particleboard screws, are self-tapping screws with thin shafts and coarse threads. They are made of carbon steel or stainless steel and then galvanized. Chipboard screws of different lengths can be used in a variety of applications. They are created to fasten low, medium and high density chipboard. Many chipboard screws are self-tapping, so there is no need to drill holes in advance.

* Material:Made of carbon steel C1022A to make the Chipboard Screw have stronger strength. Adopt high-strength rolling arm, small gap, mute, wear-resistant, uniform force.

* CSK countersunk head: The double countersunk head could help to increase head strength. The flat head helps the chipboard screw keep same level with the material.

* Groove:Most of the Chipboard Screws use the Pozi or Phillips’ The cross groove help s not slip when use the screw gun.

* Sharp Point: The Chipboard Screws with sharp point which make them easier to stab the screw into material without a pilot drill hole. The Type 17 point make the screw sharper to use.

* Surface Treatment:After a zinc plating and heat treated to make the Chipboard Screws resist corrosion and harder.

* Coarse Thread:It is sharper and deeper than the Drywall Screw’s coarse thread, which help the chipboard screw digs deeper and stay tight into the soft materials, and cut through material cleanly.

* Rib: The rib under the screw head help the screw do not slip.

* Straw Rope: The straw rope help the screw do not slip.

* Our Advantage: Adopt high-speed cold heading machine to form one piece, high strength. Self-owned heating treatment producing line,which can promise screws hardness and strength well perform always.Stable drilling speed, not easy to break.

| Dimension | Small packing | Large packing | Weight |

| (mm) | (pcs.) | (pcs.) | (kg/100 pc) |

| 2,5×10 | 1 000 | — | 0,05 |

| 2,5×12 | 1 000 | — | 0,06 |

| 2,5×16 | 1 000 | — | 0,1 |

| 2,5×20 | 1 000 | — | 0,11 |

| 2,5×25 | 1 000 | — | 0,13 |

| 2,5×30 | 1 000 | — | 0,14 |

| 3×10 | 1 000 | — | 0,05 |

| 3×12 | 1 000 | — | 0,06 |

| 3×16 | 1 000 | 45 000 | 0,06 |

| 3×20 | 1 000 | 27 000 | 0,07 |

| 3×25 | 1 000 | 17 000 | 0,08 |

| 3×30 | 1 000 | 17 000 | 0,1 |

| 3×35 | 1 000 | 17 000 | 0,11 |

| 3×40 | 1 000 | 12 000 | 0,13 |

| 3×45 | 1 000 | 10 000 | 0,14 |

| 3×50 | 1 000 | 9 000 | 0,14 |

| 3,5×16 | 1 000 | 27 000 | 0,07 |

| 3,5×20 | 1 000 | 18 000 | 0,09 |

| 3,5×25 | 1 000 | 17 000 | 0,11 |

| 3,5×30 | 1 000 | 14 000 | 0,12 |

| 3,5×35 | 1 000 | 14 000 | 0,14 |

| 3,5×40 | 1 000 | 12 000 | 0,16 |

| 3,5×45 | 1 000 | 9 000 | 0,18 |

| 3,5×50 | 1 000 | 9 000 | 0,2 |

| 3,5×55 | 1 000 | 6 000 | 0,21 |

| 3,5×60 | 1 000 | 6 000 | 0,22 |

| 4×12 | 500 | — | 0,09 |

| 4×16 | 1 000 | 25 000 | 0,1 |

| 4×20 | 1 000 | 20 000 | 0,12 |

| 4×25 | 1 000 | 14 000 | 0,15 |

| 4×30 | 1 000 | 12 000 | 0,17 |

| 4×35 | 500 | 8 500 | 0,19 |

| 4×40 | 500 | 7 000 | 0,21 |

| 4×45 | 500 | 7 000 | 0,23 |

| 4×50 | 500 | 6 000 | 0,26 |

| 4×55 | 500 | 5 000 | 0,29 |

| 4×60 | 500 | 4 500 | 0,32 |

| 4×70 | 250 | 3 500 | 0,37 |

| 4×80 | 250 | 3 500 | 0,42 |

| 4,5×16 | 1 000 | 18 000 | 0,12 |

| 4,5×20 | 1 000 | 14 000 | 0,13 |

| 4,5×25 | 1 000 | 14 000 | 0,17 |

| 4,5×30 | 1 000 | 12 000 | 0,21 |

| 4,5×35 | 1 000 | 9 000 | 0,25 |

| 4,5×40 | 500 | 7 000 | 0,28 |

| 4,5×45 | 500 | 6 000 | 0,31 |

| 4,5×50 | 500 | 5 000 | 0,35 |

| 4,5×55 | 500 | 5 000 | 0,39 |

| 4,5×60 | 500 | 4 500 | 0,44 |

| 4,5×70 | 250 | 3 500 | 0,48 |

| 4,5×80 | 250 | 3 500 | 0,53 |

| 5×16 | 500 | — | 0,172 |

| 5×20 | 1 000 | 12 000 | 0,22 |

| 5×25 | 1 000 | 10 000 | 0,25 |

| 5×30 | 1 000 | 9 000 | 0,28 |

| 5×35 | 1 000 | 8 000 | 0,32 |

| 5×40 | 500 | 7 000 | 0,36 |

| 5×45 | 500 | 6 000 | 0,4 |

| 5×50 | 500 | 5 000 | 0,43 |

| 5×55 | 500 | 5 000 | 0,47 |

| 5×60 | 250 | 4 250 | 0,51 |

| 5×70 | 250 | 3 500 | 0,58 |

| 5×80 | 250 | 3 500 | 0,66 |

| 6×25 | 200 | — | 0,4 |

| 6×30 | 500 | 5 000 | 0,44 |

| 6×35 | 500 | 4 500 | 0,5 |

| 6×40 | 250 | 3 500 | 0,56 |

| 6×45 | 250 | 3 500 | 0,61 |

| 6×50 | 250 | 3 500 | 0,67 |

| 6×55 | 250 | 3 000 | 0,71 |

| 6×60 | 250 | 2 500 | 0,75 |

| 6×70 | 250 | 2 250 | 0,89 |

| 6×80 | 250 | 2 250 | 0,99 |

1.Standard cross stot and in conformity with the PH2 screwdriver bit

2.Phosphate treatment to prevent rust

3.High hardness of sharp thread after heat treatment

4.Sharp tip for screwing in quickly