Galvanized Steel Wire Electro Galvanized Gi Iron Binding Wire for Building

Iron Wire

Electro Galvanized with 3 g to 15 g per square meter;Electro galvanized iron wire is made with choice mild steel, through wire drawing, wire galvanizing and other processes. Electro galvanized iron wire has the characteristics of thick zinc coating, good corrosion resistance, firm zinc coating, etc. It’s mainly used in construction, express way fencing, binding of flowers and wire mesh weaving.

Hot dipped Galvanized with 45 g-50 g per square meter.Hot-dip galvanized iron wire is made with choice low carbon steel wire, through wire drawing, acid washing and rust removing, annealing and coiling. It’s mainly used in construction, handicrafts, woven wire mesh, express way fencing mesh, packaging of products and other daily uses.

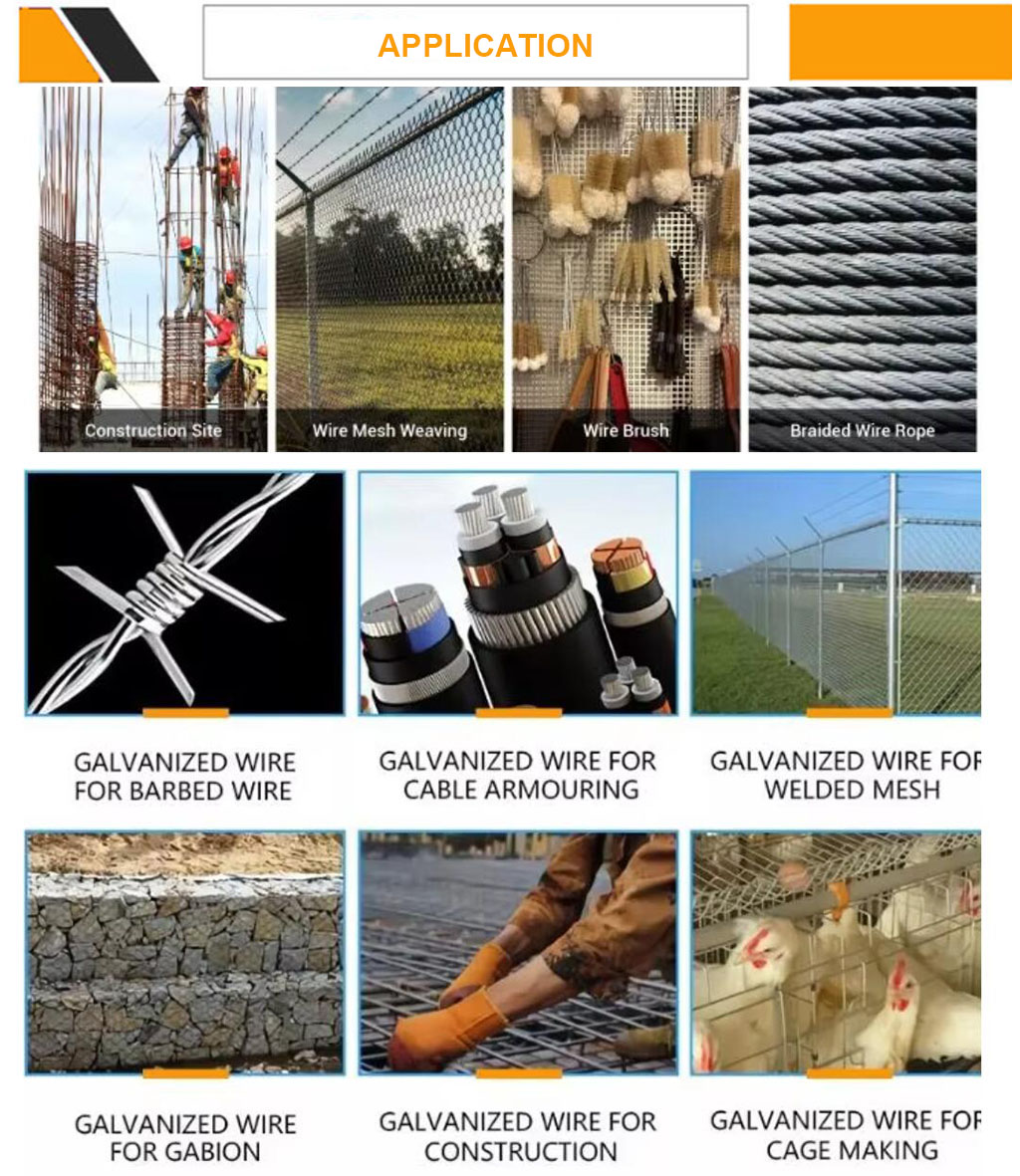

Application

* Mesh weaving.

* Tying wire in architectural site.

* Making handicrafts.

* Material of mesh and fence.

* Packing life products.

Galvanized Iron Wire:

|

wire gauge size |

SWG(mm) |

BWG(mm) |

metric(mm) |

|

8 |

4.06 |

4.19 |

4.00 |

|

9 |

3.66 |

3.76 |

- |

|

10 |

3.25 |

3.40 |

3.50 |

|

11 |

2.95 |

3.05 |

3.00 |

|

12 |

2.64 |

2.77 |

2.80 |

|

13 |

2.34 |

2.41 |

2.50 |

|

14 |

2.03 |

2.11 |

- |

|

15 |

1.83 |

1.83 |

1.80 |

|

16 |

1.63 |

1.65 |

1.65 |

|

17 |

1.42 |

1.47 |

1.40 |

|

18 |

1.22 |

1.25 |

1.20 |

|

19 |

1.02 |

1.07 |

1.00 |

|

20 |

0.91 |

0.89 |

0.90 |

|

21 |

0.81 |

0.813 |

0.80 |

|

22 |

0.71 |

0.711 |

0.70 |