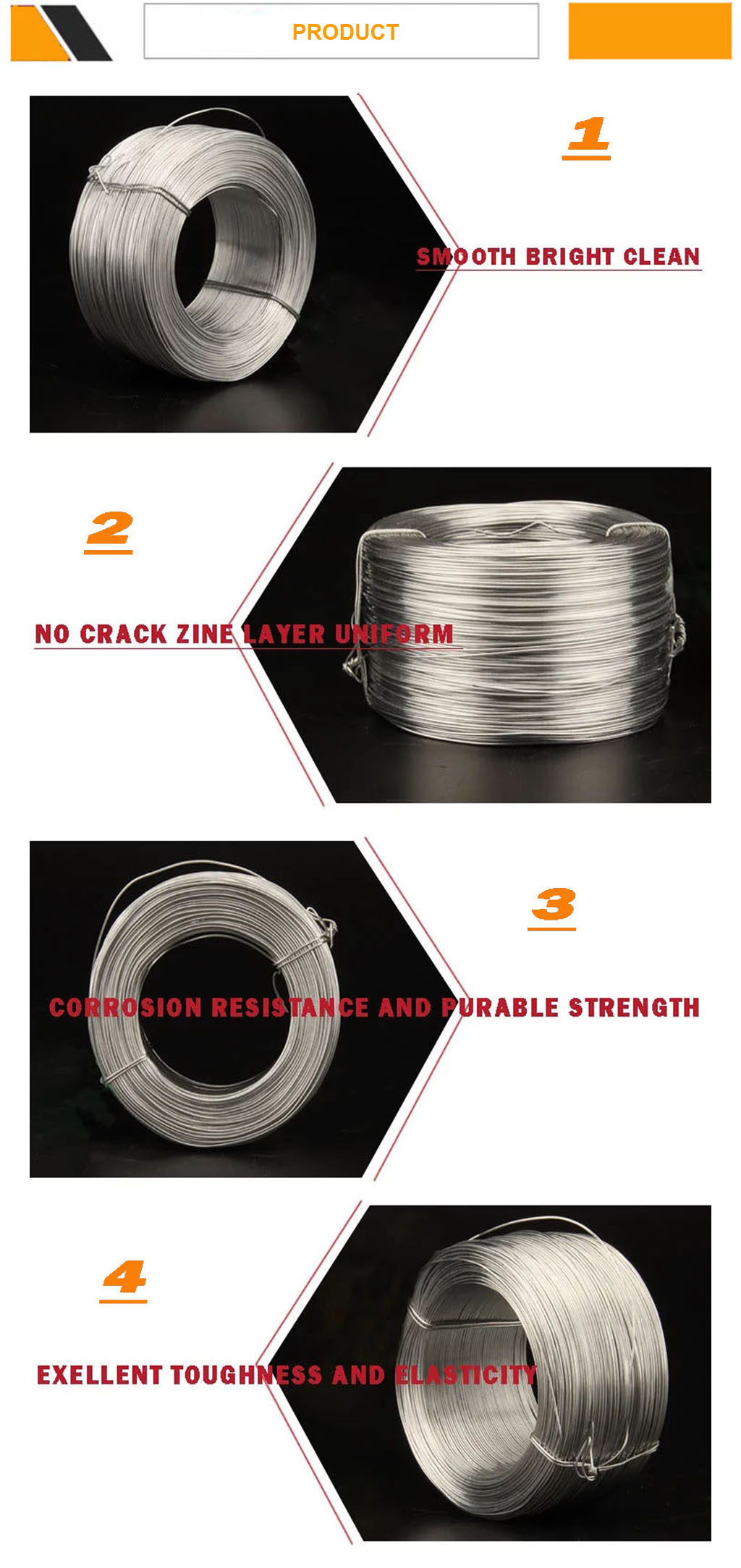

Hot sale small coil 3.5LBS banding wire for building

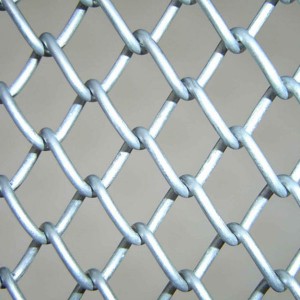

concrete construction. Black annealed rebar tie wire is the best sell material. We also supply galvanized and epoxy coated tie

wire.Before concrete is poured, tie wire is used to secure rebar in place or fasten rebar together

Manufactured to achieve a good balance between tensile strength and elongation

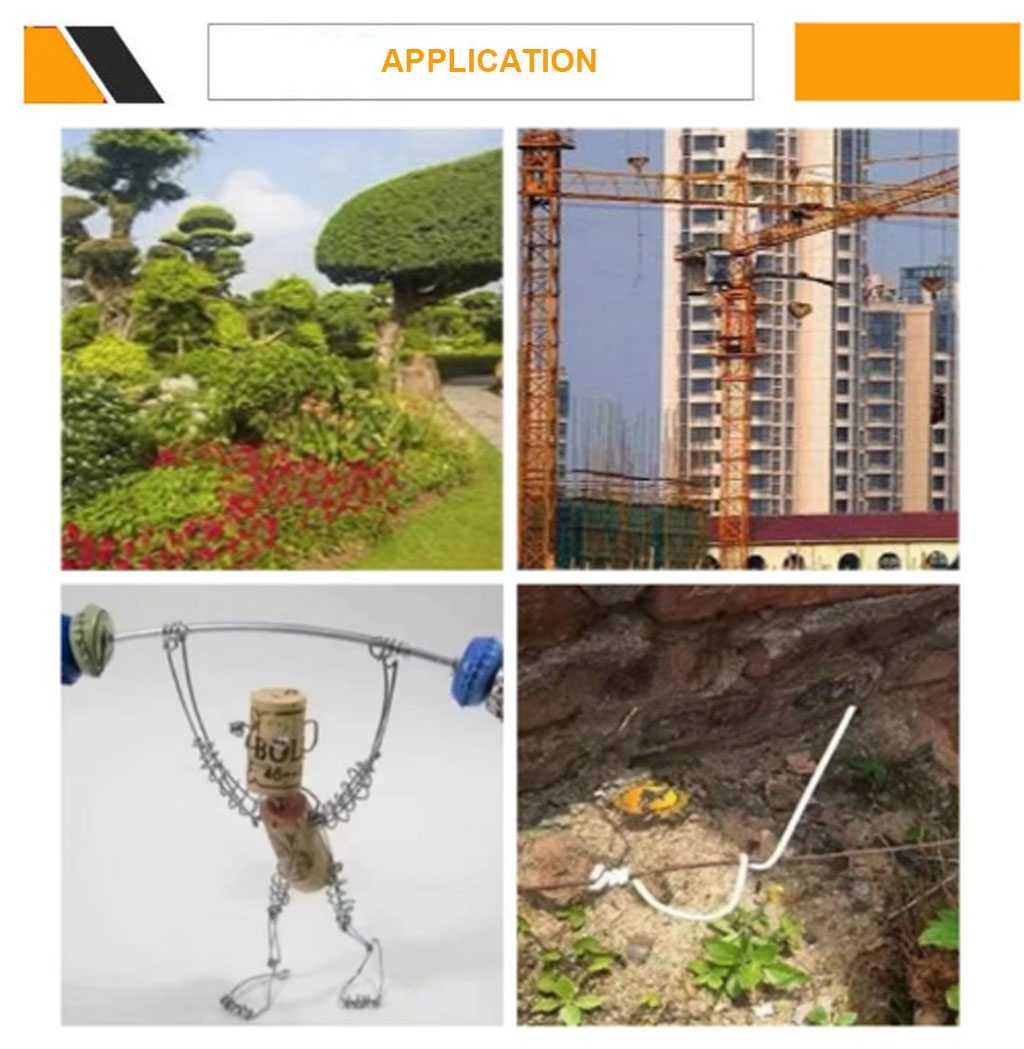

PVC Coated Wire is manufactured with quality iron wire. PVC is the most popular plastic for coating wires,as it is relatively low in cost,resilient,fire retardant and possesses good insulating properties. Common colors available for PVC coated wire are green and black. Other colors are also available on request.. Application: Mainly used as tie wire rope or in building .wire mesh production and production of civilian industry. soft annealed wire

offers excellent flexibility and softness through the process of free oxygen annealing. we can do it in straight cut wire, U type wire and also according to the special requirements of users.

Advantage Big real factory, we can satisfy you products with good quality, fast delivery and satisfied service. Galvanized wire is made of high-quality low-carbon steel wire rod, which is divided into hot-dip galvanized wire and cold-galvanized wire. Hot dip galvanizing is dipped into a heated molten zinc solution. The production speed is fast, the consumption of zinc metal is large, and the corrosion resistance is good. Cold galvanizing (electro galvanizing) is to gradually coat the metal surface with zinc through a unidirectional current in the electroplating tank. The production speed is slow, the coating is uniform, the thickness is thin, the appearance is bright, and the corrosion resistance is poor. Black annealed wire is another cold-processed product of steel wire, and the material used is generally high-quality low-carbon steel or stainless steel.

| Wire Gauge | Diameter(mm) | Tensile Strength(kg/mm2) | Zinc Coating | Coil Weight(kg) |

| 6# | 4.60-4.95 | 40-70 | 30-260 | 300-800 |

| 7# | 4.25-4.60 | 40-70 | 30-260 | 300-800 |

| 8# | 3.90-4.25 | 40-70 | 30-260 | 300-800 |

| 9# | 3.65-3.90 | 40-70 | 30-260 | 300-800 |

| 9.5# | 3.49-3.65 | 40-70 | 30-260 | 300-800 |

| 10# | 3.14-3.32 | 40-70 | 30-260 | 300-800 |

| 10.5# | 3.14-3.32 | 40-70 | 30-260 | 300-800 |

| 11# | 2.96-3.14 | 40-70 | 30-260 | 300-800 |

| 11.5# | 2.84-2.96 | 40-70 | 30-260 | 300-800 |

| 12# | 2.70-2.84 | 40-70 | 30-260 | 300-800 |

| 12.5# | 2.50-2.70 | 40-65 | 30-260 | 300-800 |

| 13# | 2.32-2.50 | 40-70 | 30-260 | 300-800 |

| 13.5# | 2.18-2.32 | 40-70 | 30-260 | 300-800 |

| 14# | 2.03-2.18 | 40-70 | 30-260 | 300-800 |

| 14.5# | 1.90-2.03 | 40-70 | 30-200 | 300-800 |

| 15# | 1.76-1.90 | 40-70 | 30-200 | 300-800 |

| 16# | 1.61-1.70 | 40-60 | 20-60 | 300-800 |

| 16.5# | 1.52-1.61 | 40-60 | 20-60 | 300-800 |

| 17# | 1.43-1.52 | 40-60 | 20-55 | 200-350 |

| 17.5# | 1.30-1.43 | 40-55 | 20-45 | 200-350 |

| 18# | 1.19-1.30 | 40-55 | 20-45 | 25-350 |

| 18.5# | 1.11-1.19 | 40-55 | 20-45 | 25-350 |

| 19# | 1.02-1.11 | 40-55 | 20-45 | 25-350 |

| 19.5# | 0.93-1.02 | 35-55 | 20-45 | 25-350 |

| 20# | 0.84-0.93 | 35-55 | 20-45 | 25-350 |

| 21# | 0.76-0.84 | 35-55 | 20-40 | 25-350 |

| 22# | 0.67-0.76 | 35-55 | 20-40 | 25-350 |

| 23# | 0.62-0.67 | 35-55 | 20-40 | 25-350 |